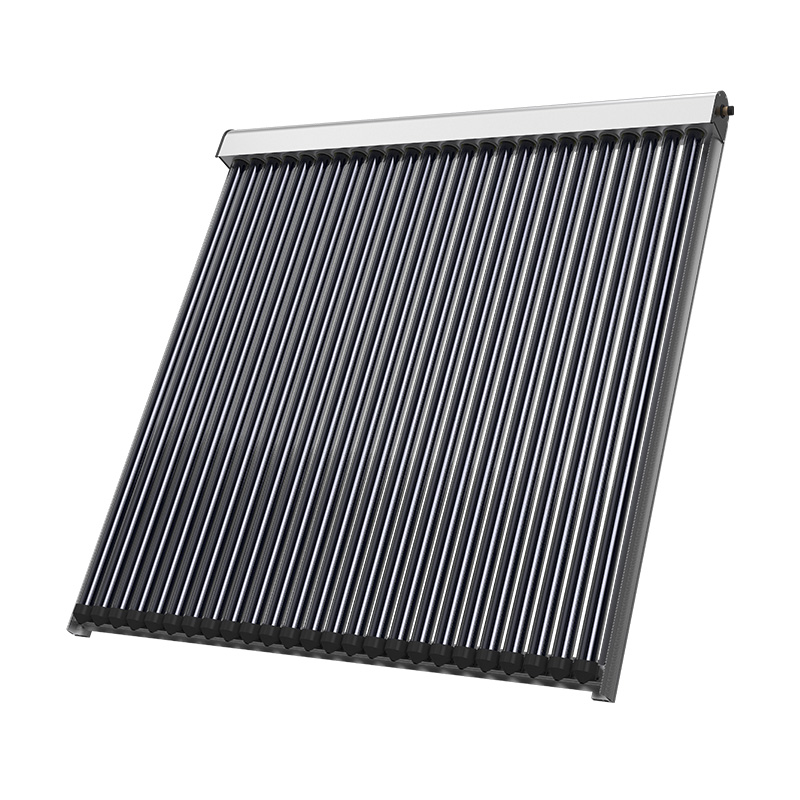

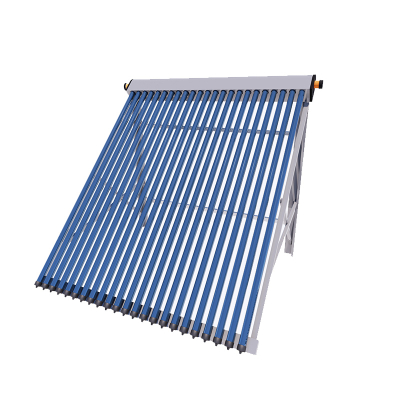

Evacuated Tube U-Type Solar Collector

The fin structure is produced using 3003 anti-rust aluminum, selected for its resistance to corrosion and stable performance under prolonged exposure to sunlight. Its high thermal conductivity supports efficient heat absorption and rapid transfer to the flow channel.

The flow channel is primarily constructed from copper, a material widely recognized for its excellent heat transfer characteristics and durability. In selected models, rare-earth alloy tubes are used to further enhance oxidation resistance and long-term material stability, particularly in demanding operating environments.

The welding process utilizes silver-copper welding rods. Compared with conventional welding materials, this approach preserves joint strength and flexibility, reducing the likelihood of cracking, leakage, or corrosion at welded connections over time.

The heat transfer medium can be selected according to ambient temperature and operating conditions. This flexibility allows the collector to maintain stable performance across different climate zones, from mild to cold regions.

Product Definition & Core Structure

The U-Tube Solar Collector is a pressurized solar thermal collector designed for centralized heating and domestic hot water systems that require long-term stability and controlled operation. Its design philosophy differs from direct water-flow vacuum tube collectors by isolating the heat transfer circuit from the user-side water system, thereby improving safety, reliability, and service life.

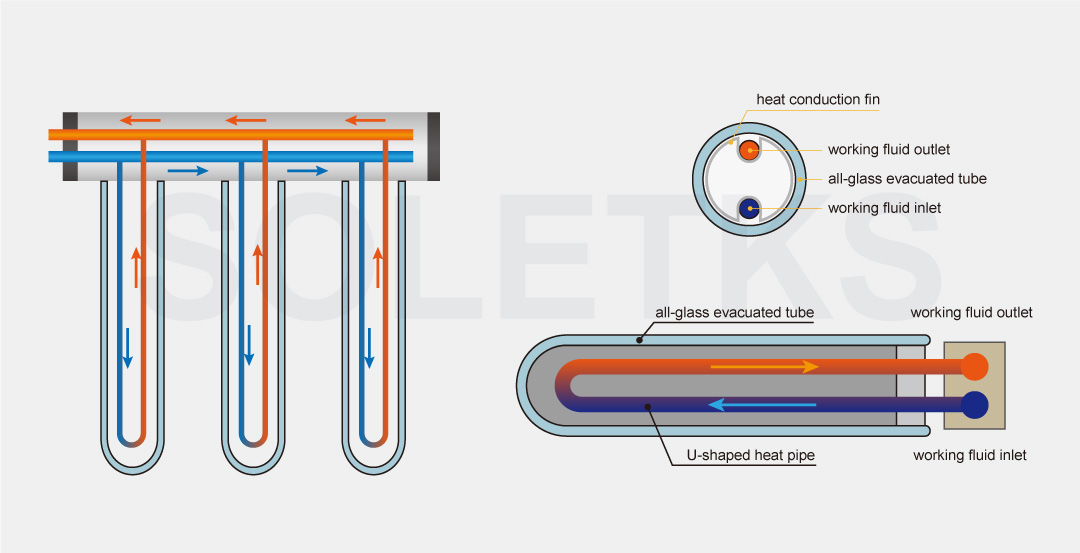

The collector is composed of U-shaped metal flow channels, evacuated glass tubes, high-efficiency aluminum fins, and an integrated header manifold. Solar radiation enters the vacuum tube through the transparent outer glass, where heat is absorbed by the fin structure inside the tube. This thermal energy is then transferred directly to the U-shaped flow channel through metal conduction.

A dedicated heat transfer medium circulates inside the U-tube, carrying the collected thermal energy to the system’s heat exchanger or storage tank. Because the heat transfer medium operates within a closed and sealed metal circuit, the collector can function under pressure without introducing water into the vacuum tube itself.

This indirect heat exchange mechanism is particularly suitable for engineered solar thermal systems, where operational continuity, system safety, and predictable heat output are more critical than short-term thermal response. As a result, U-tube collectors are widely used in centralized installations rather than individual household units.

Application Scenarios

The U-Tube Solar Collector is designed to support a wide range of centralized solar thermal applications, especially in projects where system reliability and lifecycle performance are prioritized.

In residential complexes, the collector is commonly used in centralized domestic hot water systems serving apartment buildings or residential communities. Pressurized operation allows seamless integration with modern plumbing infrastructure, ensuring stable water pressure and consistent hot water delivery. The absence of water inside the vacuum tube eliminates freezing risks in winter and overheating issues in summer.

For commercial buildings, such as hotels, hospitals, schools, and entertainment facilities, hot water demand is typically continuous and concentrated. The U-tube collector provides stable thermal output and supports long-duration operation, making it suitable for facilities that cannot tolerate frequent system interruptions or maintenance shutdowns.

In industrial parks and industrial heating projects, U-tube collectors are often used for process water preheating, space heating, or as part of hybrid energy systems. The use of glycol-based heat transfer fluids allows reliable performance in cold climates, including northern regions with extended low-temperature periods.

Overall, the U-tube collector is best applied in systems that require centralized control, predictable energy output, and long-term operational reliability rather than decentralized or short-cycle heating scenarios.

Key Advantages

Safe and Stable Operation

A key advantage of the U-tube solar collector lies in its inherently safe operating principle. The system supports pressurized operation while ensuring that no water flows directly through the vacuum tubes. This design fundamentally avoids common failure modes such as tube rupture caused by overheating during peak summer conditions or freezing damage in cold winter climates.

Because the heat transfer medium circulates inside a sealed metal channel, the collector is not affected by water quality issues. Problems such as scaling, corrosion caused by mineral content, and leakage associated with water-filled tubes are effectively eliminated. This significantly enhances system safety and reduces maintenance requirements over the collector’s service life.

High Heat Transfer Efficiency

The U-tube collector adopts a secondary heat exchange structure based on a U-shaped metal flow channel. Heat absorbed by the fin structure is transferred efficiently through direct metal contact to the circulating heat transfer medium. This configuration ensures stable heat transfer performance under varying solar radiation and operating conditions.

While the thermal response may be more controlled compared to heat pipe systems, the U-tube design provides consistent efficiency over extended operating periods, making it suitable for projects that emphasize steady energy delivery rather than rapid thermal cycling.

Durability and Corrosion Resistance

All heat transfer components are enclosed within a sealed flow channel, effectively isolating them from external environmental influences. Copper and selected rare-earth alloy materials are used to provide strong corrosion resistance and thermal stability.

In addition, high-toughness welding techniques are applied at all joints to maintain structural integrity under repeated thermal expansion and contraction. This robust construction reduces the risk of long-term degradation and contributes to extended service life.

Customizable Design and Architectural Integration

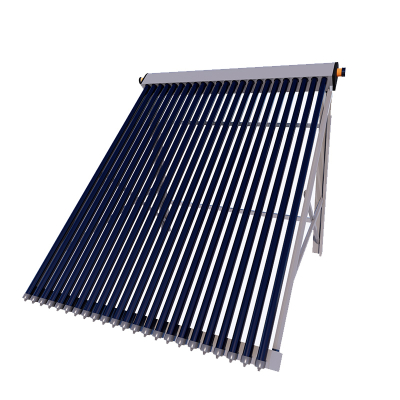

U-tube collectors can be customized in terms of size and configuration to meet specific project requirements. Their modular structure allows flexible arrangement within collector arrays, supporting various system layouts.

The collector frame is manufactured from GM aluminum alloy profiles, providing high mechanical strength and ease of installation. The brushed silver surface finish enhances visual consistency with modern architectural designs, making the collector suitable for both functional and appearance-sensitive installations.

Component & Material Advantages

The fin structure is produced using 3003 anti-rust aluminum, selected for its resistance to corrosion and stable performance under prolonged exposure to sunlight. Its high thermal conductivity supports efficient heat absorption and rapid transfer to the flow channel.

The flow channel is primarily constructed from copper, a material widely recognized for its excellent heat transfer characteristics and durability. In selected models, rare-earth alloy tubes are used to further enhance oxidation resistance and long-term material stability, particularly in demanding operating environments.

The welding process utilizes silver-copper welding rods. Compared with conventional welding materials, this approach preserves joint strength and flexibility, reducing the likelihood of cracking, leakage, or corrosion at welded connections over time.

The heat transfer medium can be selected according to ambient temperature and operating conditions. This flexibility allows the collector to maintain stable performance across different climate zones, from mild to cold regions.

Technical Specifications

| Collector Model | U-tube318 | U-tube395 | U-tube472 |

| Dimensions (mm) | 1720×1936×156 | 2120×1936×156 | 2520×1936×156 |

| Vacuum Tube Size | φ58×1800 | φ58×1800 | φ58×1800 |

| Number of Tubes | 20 | 25 | 30 |

| Total Area (m²) | 3.18 | 3.95 | 4.72 |

| Absorber Area (m²) | 2 | 2.5 | 3 |

| Net Weight (kg) | 67 | 86 | 102 |

| Working Pressure (MPa) | 1 | 1 | 1 |

| Connector Size | G3/4" Thread | G3/4" Thread | G3/4" Thread |

| Number of Connectors | 2 | 2 | 2 |

| Total Heat Loss Coefficient | 2.252 W/(m²·K) | 2.252 W/(m²·K) | 2.252 W/(m²·K) |

| Max Working Temperature (°C) | 120 | 120 | 120 |

| Peak Efficiency | 0.701 | 0.701 | 0.701 |

| Rated Efficiency | 0.59 | 0.59 | 0.59 |

| Rated Output @400 W/m² (kW) | 0.34 | 0.42 | 0.5 |

| Rated Output @700 W/m² (kW) | 0.76 | 0.95 | 1.62 |

| Rated Output @1000 W/m² (kW) | 1.18 | 1.47 | 1.77 |

| Water Tank Capacity (L) | 3.84 | 4.8 | 5.75 |

Why Choose Soletks Solar

As an original manufacturer, Soletks Solar provides U-tube collectors with full customization capabilities to match specific project requirements. With six production bases and a vertically integrated supply chain, the company ensures reliable production capacity and consistent delivery performance.

Each collector undergoes more than 60 quality inspection procedures, supported by AI-assisted quality control systems to maintain a high product qualification rate. Backed by 117 patented technologies and a comprehensive research and development system, Soletks Solar supports projects from component selection through complete system integration.

With over 20 years of experience in clean thermal energy applications, Soletks Solar has successfully delivered solutions for building heating, industrial thermal processes, agricultural drying, and cold-climate installations.